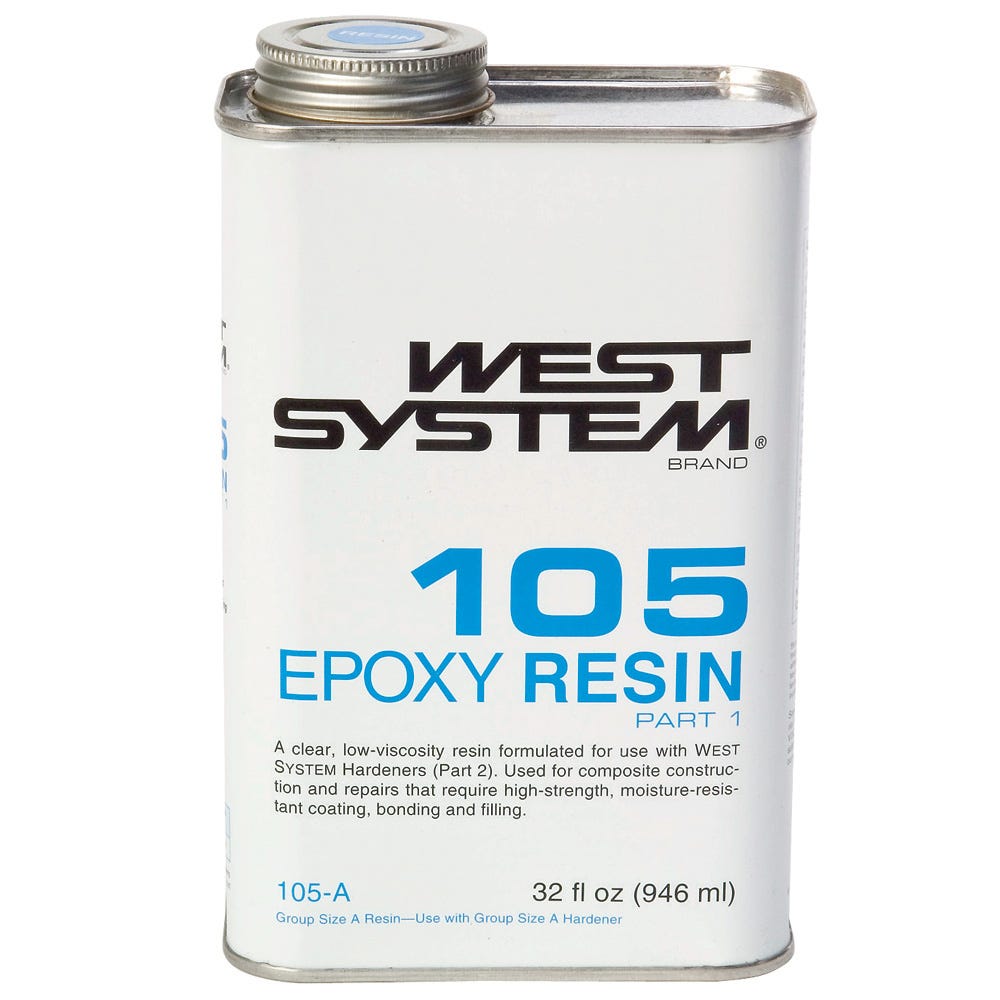

WEST SYSTEM® Epoxy Resin

Item #

GRP17645_1

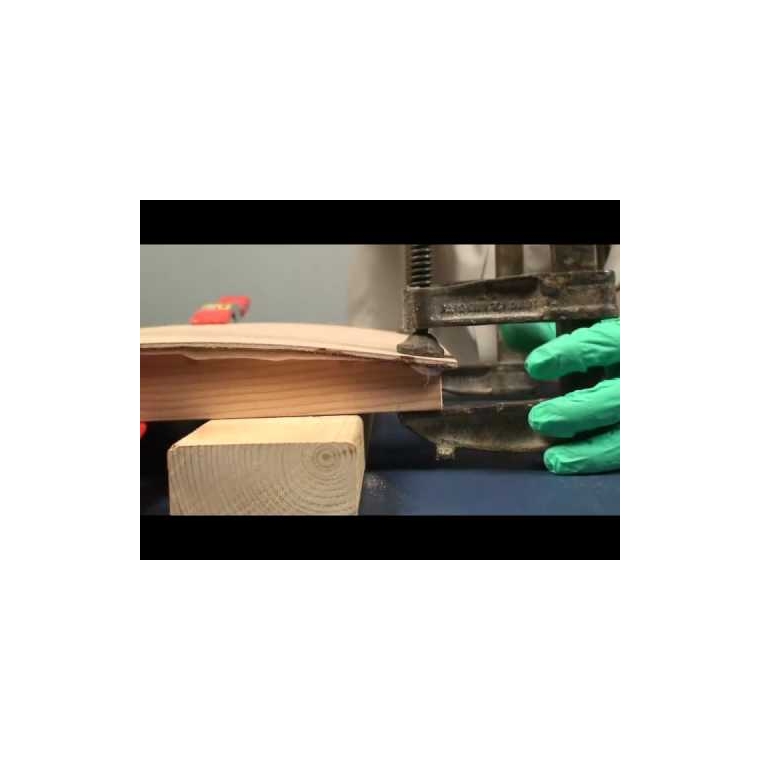

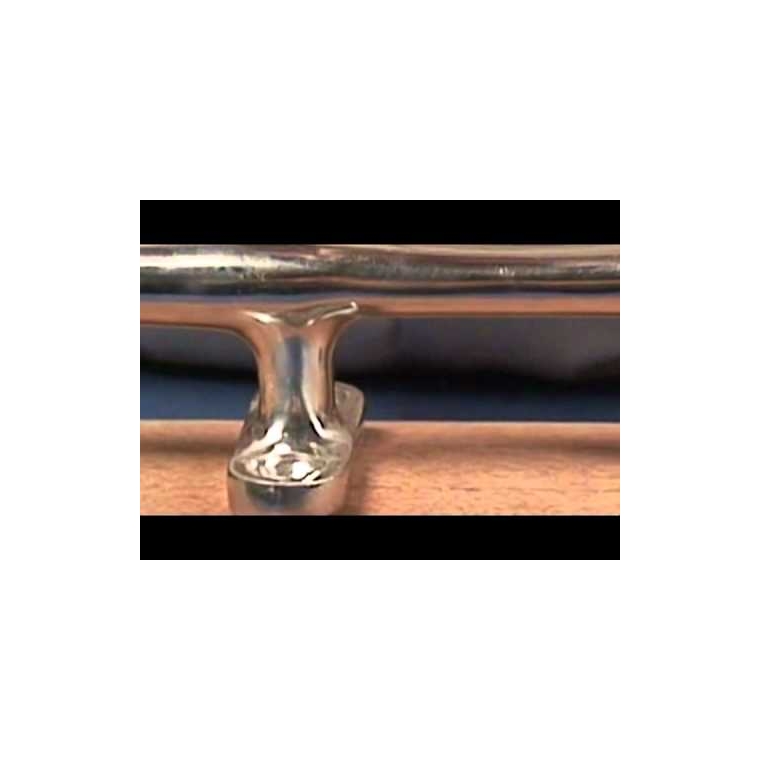

WEST SYSTEM Epoxy 105 Resin when mixed with a WEST SYSTEM Epoxy Hardener is an ultra-tough waterproof coating, a high-strength, gap filling adhesive or an easily sanded surface filler for wood, fiberglass, reinforcing fabrics and a variety of metals. More details

How do you want your item?

Delivery

Check In-Store Availability

Check availability in your nearest store

Crafting with Wood: Turn Your Ideas into Reality

Create with wood! Our premium materials make your projects come to life...Read More

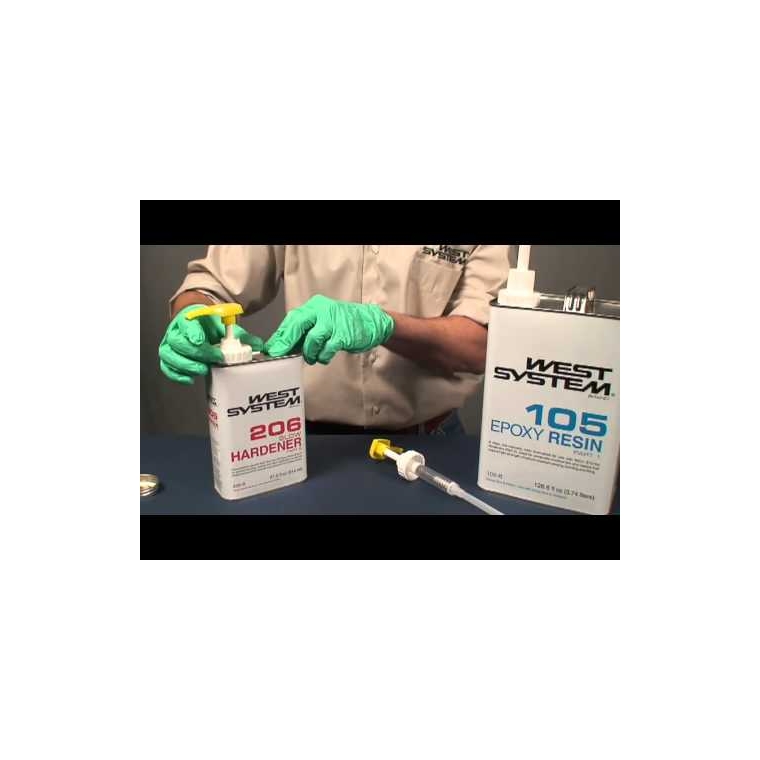

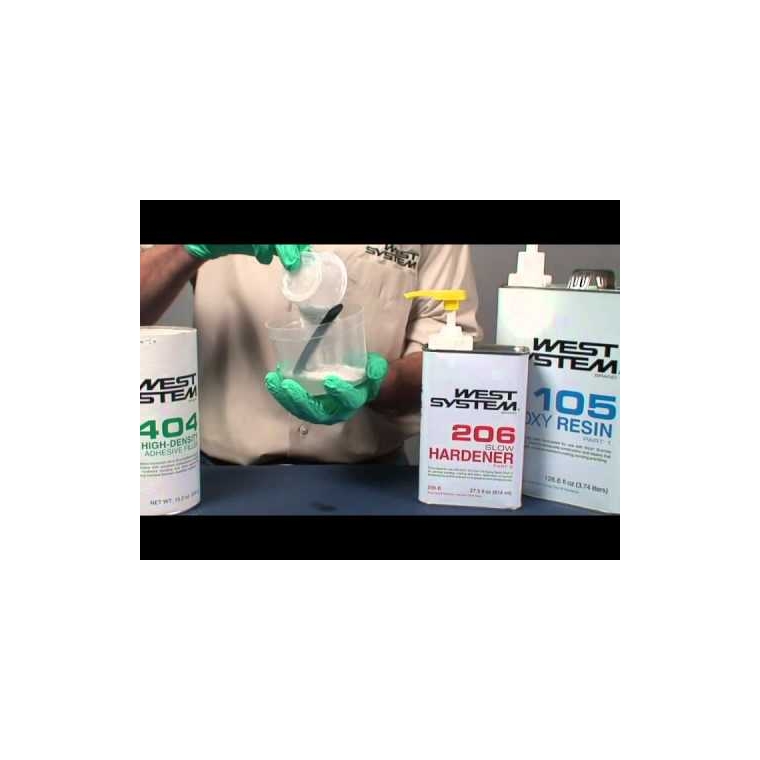

The 105 Epoxy Resin is the base material of the WEST SYSTEM family. A clear, pale yellow, low-viscosity resin, 105 forms a high-strength solid with excellent moisture resistance, and is designed specifically for wood fiber, fiberglass, reinforcing fabrics and a variety of metals. The Resin works in conjunction with a variety of WEST SYSTEM Hardeners, Fillers and Pumps for a wide range of applications.

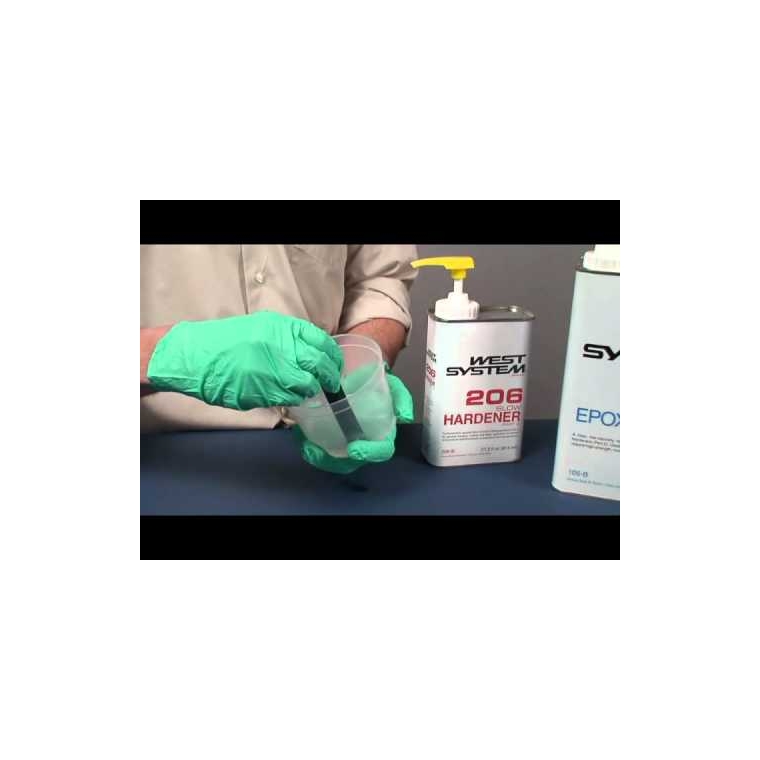

Combined with 205 Fast, 206 Slow and 209 Extra-Slow Hardeners (sold separately), the cure time of 105 can be fine-tuned and adjusted for a wide range of temperatures. For coating and roller applications, it can be combined with 207 Coating Hardener, which provides excellent thin-film characteristics to flow out and self-level without "fisheyeing." Cures clear to light amber, so you can achieve a natural wood finish when coating with varnish.

(1) WEST SYSTEM® Epoxy Resin

| Brand | West System |

|---|---|

| Weight | 10.34 |

| Tech Spec |

|