Delivery

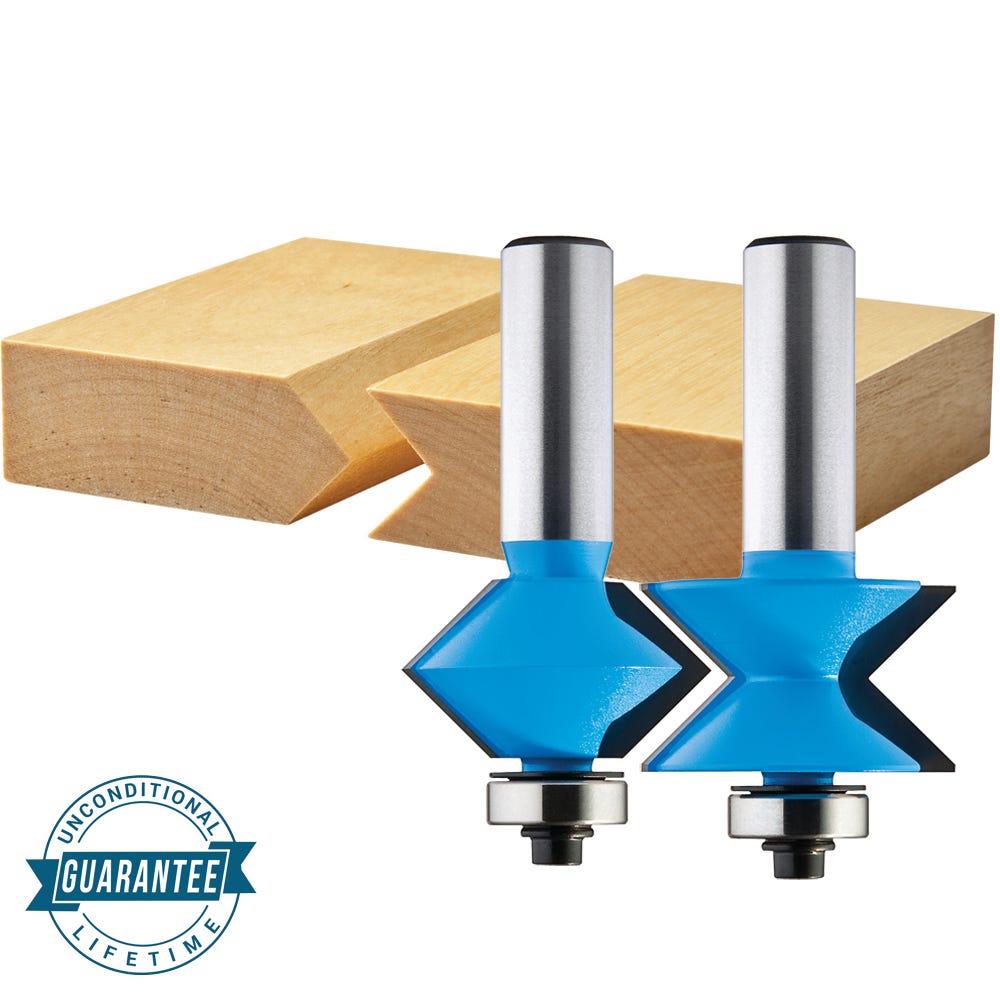

Rockler Edge V-Groove Router Bits - 1/2" Shank

Item #

GRP25328

Interlocking profiles self-align and increase available gluing surface, making them ideal for edge joining boards. More details

How do you want your item?

Check In-Store Availability

Check availability in your nearest store

Crafting with Wood: Turn Your Ideas into Reality

Create with wood! Our premium materials make your projects come to life...Read More

Mill the edges of your panel stock with these interlocking V-Groove Bits, and you'll never have to worry about misaligned boards again. When it's time to clamp up an edge joint, the parts slide into perfect alignment without any twisting, prying or hammering. The deep channel created by the V-Groove Bit also increases the available glue surface of the joint, creating a much better glue bond. Ideal for applying solid wood edging, and for gluing up solid wood panels. All feature sturdy 1/2" shanks to maximize rigidity and cut quality.

If a Rockler Router bit fails to perform for any reason we will replace it. No proof of purchase required. Exchange the product at your local Rockler retail store or mail it to Rockler at 4365 Willow Dr. Medina MN 55340. Name and address must be included in the package to process the exchange.

Tool Compatibility

(1) V-Groove Edging Bit, 1/2" Shank

| Brand | Rockler |

|---|---|

| Weight | 0.27 |

WARNING:

- Cancer & Reproductive Harm - www.P65Warnings.ca.gov

WARNING:

- Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer. Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood.

WARNING:

WARNING: