Assembling Hardwood Pieces Using Flat Head Wood Screws

In a world of whizz-bang gadgets and high tech tools, a recent thread on a woodworking forum reminded me that sometimes we need to stop, rewind and get back to the basics. The poster was lamenting that he had no idea how to drive a screw. This may seem silly, but it really is an honest question.

As a cabinet maker I use high tech, square drive, self drilling screws with nibs under the head that help them sink without dimpling the plywood Just drive it and move on to the next. But as a builder of reproduction furniture, I often need to assemble hardwood pieces using (gasp!) old fashioned, flat head wood screws.

How To Drive A Screw Without Splitting The Wood

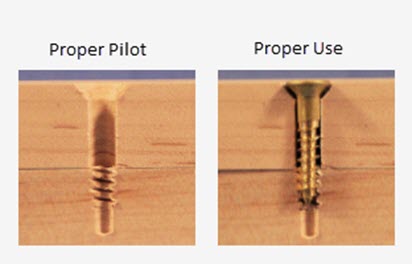

Just forcing a common wood screw in would tend to split the wood, and often the two parts will not draw together properly. A pilot hole is needed. Actually, two pilot holes are needed. Well, ok. What we really need is two pilot holes of different diameters and a countersink so that the screw head does not protrude above the part.

When joining two parts like a frame and table top, the frame needs a hole big enough so that the screw can pass through, but not so big that the head will. The top needs a hole wide enough to accommodate the body of the screw without splitting, but not as wide as the threads or they will not hold. The two different holes allow the threads to twist into one part while not binding in the other.

Lastly, a countersink in the through hole sets the screw head slightly below the surface. Waxing or otherwise lubing the screw can help keep the head from twisting off, especially with brass screws. Fortunately, there are good options for drilling all of these at once. Tapered drills create a larger hole above, and narrower at the tip.

Typically, this is a compromise, but works pretty well. Add a countersink to the tapered bit, and all three operations can be covered in one. The countersink is even adjustable along the tapered bit so you can set the proper drill depth. Hmmm, we seem to have come full circle, back to a whizz-bang tool that helps us work faster.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks