Longleaf Pine: Pinus palustris

When you compare longleaf pine to most of its cousins, it actually has more in common with hardwood lumber — in terms of density, durability and workability — than softwoods (say Norway or white pine, for example). Its resinous nature makes it moderately rot-resistant. Quartersawn longleaf pine presents a lovely straight-grained figure that evokes old-growth Douglas fir, but with a creamier background offset by rich reddish and orange hues. It can be stunningly beautiful to look at.

While it is a true softwood, to think of longleaf pine in terms of its more common pine lumber cousins would be a serious disservice to this unique wood, akin to comparing a Ferrari to a Ford Focus simply because they both have wheels.

Trial by Fire

Longleaf pines grow up to 130 feet in height and three feet in diameter. They are the longest living of all southern yellow pines, known to live more than 300 years. They produce the highest quality wood of all North American pines. Their self-pruning growth leads to few knots. Growth rings are thin and tightly spaced.

Frequent fires in its natural habitat developed the longleaf's system of sporadic seed production. It sprouts but does not begin growth for six to 10 years as it puts down a taproot. During this stage, the seedling is known to be in the "grass" stage because it looks very similar to bunch grass. These seedlings wait for some natural event that removes the canopy, providing sunlight to the forest floor and allowing the seedlings to begin to grow. During the grass stage (and any other time they are not actively growing), they can survive intense fires, as can the mature trees.

Longleaf pine once grew in the coastal plain from southeastern Virginia into southern Florida and west into eastern Texas, as well as in the low mountains of Alabama. This ecosystem had occupied up to 94 million acres, but by 1995 it had shrunk to just three percent of its native range. This is mostly federal and state lands and a handful of large plantation estates. Luckily, what remains is managed and responsibly harvested.

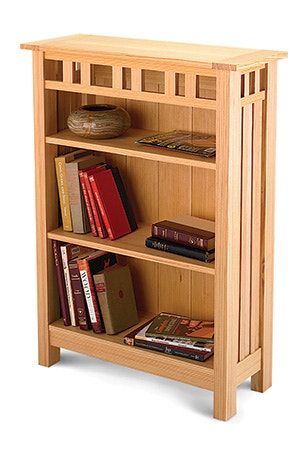

Presently, most newly harvested longleaf lumber goes into the building trades for flooring and structural uses where extreme strength is required. But woodworkers are beginning to rediscover the beautiful nature of longleaf and use it more and more in furniture making.

Shop Score Card

|

Uses: Construction lumber, porch decking and exterior trim. Furniture construction and panels. Hardness: Medium density with good strength properties. High resin content resists bending. Country of Origin: Southern United States. Workability: Cuts and planes cleanly with power tools. Can be difficult to hand plane. Hard resin structure produces crisp profiles. Glues, nails and screws well, although thin drill bits can wander . Finishing: Contrasting grain density stains inconsistently. Prefinishing with shellac is advisable. Cost: Wide availability and sustainable harvesting make this an inexpensive softwood. |

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks