RIKON 70-3040 Lathe with Sliding Bed

Motorized expanding bed — an industry first — doubles distance between centers and increases usable swing.

Length matters with wood lathes — whether it's their swing over bed or the distance between centers. Unless a lathe has a movable headstock, there's not much you can do to increase swing, and lengthening the bed to turn longer spindles requires buying a bolt-on bed extension.

RIKON has an industry-first solution to increase both of these capacities on its new 70-3040 Heavy Duty VSR Lathe: allow the bed to slide open. That's why this lathe stacks two slabs of solid steel bed together. When they're closed, the distance between centers is 20" and the swing over bed is a tad over 23". But turn a dial on the machine's controller, and a separate 24-volt DC motor under the bed extends the two sections apart, doubling the distance between centers to 40" and adding another 8" of swing for turning large bowls or platters. Net result: you get more turning capacity "on demand" without changing the machine's overall footprint.

Heavy-duty Chops

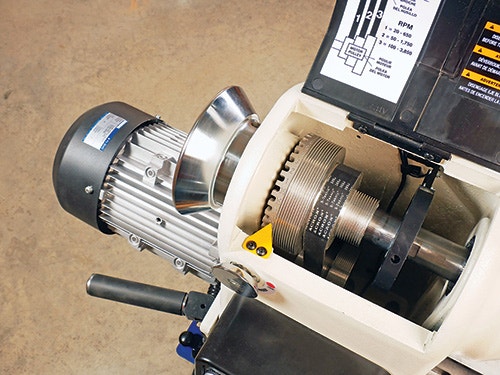

A powerful 3hp three-phase TEFC motor drives this lathe’s 1-1/4" x 8 tpi spindle, which spins in the headstock casting on four bearings to better distribute axial loads. An onboard inverter enables the motor to be powered by single-phase 220-volt power, and it also allows for variable speed — from a knuckle-dragging 20 rpm to 3,850. Shifting a multi-V drive belt between three spindle pulleys subdivides the speed range, and a large, bright LED readout reports the current speed.

The machine's control box, which houses the On/Off, forward/reverse, speed dial and bed expanding switches is tethered to the lathe with a coiled power cord. You can move and stick it to any metal surface on the lathe for greater turning convenience, thanks to its magnetic back.

RIKON provides a massive cast-iron banjo and 12" toolrest with 1" post to handle heavy-duty cuts. They lock solidly. The leading edge of the tool-rest is a hardened steel rod, which will better resist dings that can impede smooth, fluid tool use.

The 70-3040's cast-iron tailstock has a handy storage compartment hidden behind a magnetized door to hold the included drive and live centers. The tailstock's quill extends 41-1⁄16" for hole-boring operations, and both it and the headstock spindle have #2 Morse tapers.

Thick, welded steel legs help to dampen vibration during use. You can add swiveling feet to adapt the lathe's footing for uneven shop floors. Or consider an optional caster set to help move this 546 lb machine around. Several other accessories, such as a gap bed insert, are also available.

Shop Score Card

|

Swing Over Beds: 23-7/32", 31-1/4" Distance Between Centers: 20" to 40" Motor: 3hp (14.8 amp), 220-voltVariable Speed Range: 20 - 3,850 rpm Working Height (Floor to Spindle): 44" Net Weight: 546 lbs Spindle: 1-1/4" x 8 tpi Tool-rest Length / Post Dia.: 12" / 1" Indexing Positions: 36 Quill Travel / Spindle, Tailstock Tapers: 4-11/16" / MT2s |

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks