Sorting Through Sharpening Systems

Keeping Tools Sharp - One Size Does Not Fit All How seriously should you take keeping your tools sharp? Ask around and you'll get a range of opinions. For some woodworkers, sharpening is at best a necessary evil - to be taken up only when a tool will no longer successfully cut wood. For others, the practice of keeping every chisel, plane iron, gouge, saw blade and pencil in the shop in absolute razor-sharp condition carries an almost spiritual significance. Most, however, would take a more moderate position. They'd say - as so many professional woodworkers have - that reasonably-to-very sharp tools, and a system for keeping them that way, are prerequisites for enjoyable, accurate and safe work.

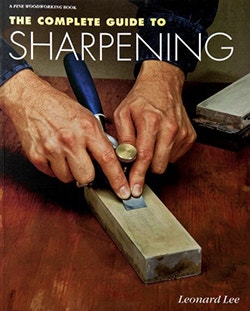

The Venerable Benchstone

One of the most familiar sharpening tools is the good old bench stone. Benchstones come in a variety of types and materials, each of which has it's own unique properties. In general, sharpening stones can be divided into three basic groups: oilstones, water stones, and diamond stones.

There's nothing wrong with the bench stone method of keeping an edge on your tools - as long as you don't mind supplying a little elbow grease. in fact, sharpening systems that make use of various natural and man-made abrasive materials are still among the most popular.

It would be possible to devotee several chapters in a book to a treatise on benchstone sharpening techniques - in fact several people have. One of our favorite, Leonard Lee's The Complete Guide to Sharpening, provides in depth information on just about every sharpening task you'll run into, and is highly recommended reading for anyone who's just beginning to take sharpening seriously. But in short form, here is how the various stone differ: Oilstones have traditionally been the favorite here in the West, and are still among the most popular.

Oilstones are lubricated with oil during the cutting process, and may be made of naturally occurring or man-made materials. Oilstones are available in a variety of degrees of coarseness, from fast-cucd Black Arkansas stone. Oilstones tend to wear well and require less flattening than waterstones. While naturally occurring oilstone is less plentiful and more costly than in the past, a one-time investment can last a lifetime.

Waterstones originated in Japan, and cut much faster than oilstones. They are also available in finer grades, which makes them a popular choice for honing and polishing devotees. Waterstones also wear much faster than oilstones and have to be flattened periodically on a lapping bed, or with a flattening stone. Diamond stones, by contrast wear like iron. A diamond stone, as the name suggests, is made from diamond crystals bonded to a steel plate. These man-made stones are typically more expensive than other types of stone, but have the advantage of staying perfectly flat regardless of how many times they have been used.

The Scary Sharp (and Very Affordable) System scary sharp

If you're the frugal type, and like to maintain intimate contact with the sharpening process, you might want to look into the Scary Sharp (tm) system. What's Scary Sharp? It's a method, not a thing. Scary Sharp means using successively finer grits of wet/dry sandpaper and a lubricant to sharpen tools. There is some debate as to the origin of the Scary Sharp system; some believe that it predates World War II, and has been passed down from master to apprentice for generations. Although this now-classic account is not the origin of Scary Sharp, as many believe, it is one of the best, and certainly the most entertaining, endorsements of the practice available. The key to success with the scary sharp system is having the right "equipment." That means having a range of wet/dry sandpaper grits, a honing guide to maintain the correct bevel angle, and a perfectly flat surface to work on.

Motorized Systems

The Scary Sharp (tm) system is certainly the most affordable of sharpening systems, and many woodworkers swear by it for sharpening bench chisels, plane irons and the like. Carvers, turners and other woodworkers who have (or anticipate developing) large collections of cutting tools may prefer a motorized system for its versatility and advanced features. Outfitting yourself with a respected motorized system is a significant step up in cost, but if you are a serious hand tool user, and like to keep all of your expensive cutting tools in top condition, the added cost may turn out to be a bargain in the long run. A motorized sharpening system should not be confused with a bench grinder. A typical bench grinder is best suited for quickly removing material from a metal object, and is not a good choice for the delicate operation of sharpening a fine hand tool. A sharpener's grindstone moves much slower than a bench grinder's, and it usually delivers coolant to the grinding/sharpening operation - most often, a stream of water. The cooling system prevents over-heating that would affect the hardness of the tool; the slower speed makes the grinding operation easier to control, and also prevents centrifugal force sufficient to drench the operator with coolant.

Water-cooled Sharpening Systems

In the world of water-cooled sharpening systems, there is no more respected name than Tormek. There are several reasons for this longstanding position of honor. Chiefly, the Tormek system lets you grind a variety of tools reliably and repeatably. An array of jigs available for the Tormek mean that you can grind gouges, skews, chisels and a variety of other tools time and time again at the exact same bevel angle. More recently, Jet Tools released it's own motorized sharpening system: The Jet Slow Speed Wet Sharpener. In many ways comparable to the Tormek, the Jet offers an impressive list of optional jigs and accessories, and at the same time is a little easier on the checkbook. Being able to do that is a great advantage: Once you've established the correct cutting geometry for a given tool, you can restore it in successive sharpenings reliably and with the minimum of material removal.

The Work Sharp Sharpening System

There are countless committed disciples of wet sharpening systems like the Tormek and Jet's Slow Speed Wet Sharpener. And in the opinion of many, there's no reason to look further. That notwithstanding, we'd like to mention one relative newcomer: the Work Sharp Sharpening System. Available in two models, the Work sharp is (in a sense) a hybrid of the Scary Sharp system and a motorized sharpener; it has a couple of features that you don't see every day. First of all, The Work Sharp 3000 sharpening system is an air cooled system, the convenience of which may appeal to some who think a water cooled system is a hassle. Both Work Sharp models have a unique angled sharpening port leading to the underside of the abrasive disk. The port makes it practically foolproof to sharpen straight chisels and plane irons at the proper bevel angle evenly and repeatably.

To make matters even easier, the sharpening port has an integrated, patent-pending ceramic oxide lapping abrasive on its surface. With a few quick strokes, you both sharpen the tool and remove the resultant burr from the cutting edge. If the angled sharpening port is clever and efficient, the system has yet another feature that's downright ingenious: the Work Sharp's proprietary "Edge-Vision" sharpening method. Both Work Sharp models come with special slotted sharpening wheels and corresponding slotted abrasive disks which allow you to sharpen gouges and other non-straight edged tools on the underside of sharpening wheel while you watch the goings-on through the top of the wheel (in much the same way as you can "see through" the blades of a window fan when it's running). How do the WS2000 and WS3000 differ? The WS3000 is the luxury model; it comes with all the capabilities described above and includes few appreciable refinements. The chisel and plane iron port is adjustable in five degree increments from 20 to 35 degrees, giving you more say in choosing a bevel angle, along with the ability put on a quick and easy to re-hone 5 degree micro-bevel. And not that you'll need to worry about it much, the lapping abrasive is replaceable.

The WS3000 turns slower than the WS2000 and probably feels a little smoother to operate. It also comes with two tempered glass wheels - the traditional guaranteed-flat substrate for abrasive paper sharpening. The glass wheel are two sided, adding the advantage of being able to keep each of four grinding surfaces loaded up with a different grit for fast changeovers. The Work Sharp WS2000 has one standout feature to separate it from the WS3000: the price. At around $100, we feel confident in saying that it's the most sharpener for the money that you're ever likely to get. If what you want mainly is a tool that quickly and repeatably grinds and hones straight chisels up to 1-5/8" at a perfect 25 degree bevel angle, it's a pretty good bet. And on top of that, you'll get the handy "Edge-Vision" capability and plenty of tool rest-supported freehand grinding surface on top for larger tools.

There's No Wrong Answer

In the end, just about any sharpening system will keep your tools sharp. The best one for you may depend more on your temperament and budget than on anything else. But one thing is true for everyone: once you reached a certain point in woodworking, you understand that keeping your tools sharp isn't an optional pursuit - it's a (necessary) part of the job.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks