All categories

Workshop Setup & Tool Maintenance

-

Categories: Workshop Setup & Tool Maintenance , Routers and CNCs , Skill Builder Videos , How To GuidesJanuary 16, 2025What are the first router bits you should purchase to use with your router? The router is one of the most useful and versatile woodworking tools in any shop. Of course it's not much good withoutRead more

-

December 23, 2024Make the perfect DIY workbench, cabinet, work table or shop cart for your workshop using the Rock-Steady cabinet frames.Read more

-

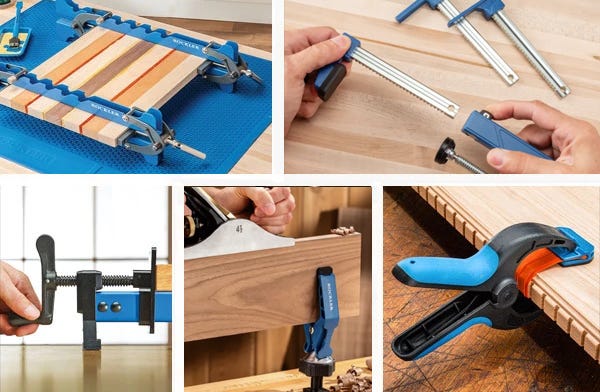

December 20, 2024Our most popular and useful woodworking clamps. Plus, some new innovations you won't find anywhere else.Read more

-

November 06, 2024What are the most common types of woodworking hand planes? Which wood hand planes do you need? Learn the best applications for each type of hand plane and how to set up and use a hand plane.Read more

-

Categories: Workshop Setup & Tool MaintenanceSeptember 01, 2024Choose the best accessories to make the most of your dust extractor.Read more

-

August 30, 2024Upgrade your dust collection system with these innovative dust collection fittings and hoses. Whether you're setting up a complete dust collection system or just looking for a specific fitting, these hoses andRead more

-

July 26, 2024Packed with features, one of the best portable vacuums for your workshop is the Dust Right Tool-Activated HEPA Dust Extractor.Read more

-

May 13, 2024Organize any drawer—and keep it that way—with the Rockler Drawer Organizer System.Read more

-

Categories: Workshop Setup & Tool MaintenanceMay 09, 2024These tips will help you sharpen tools with a game plan and tool recommendations for better success.Read more

-

Categories: Workshop Setup & Tool MaintenanceApril 16, 2024These space-saving workshop tables are strong, sturdy, and easy to store when you're not using them. Some act as a table top extension. Others are stand-alone work tables that fold up to save space.Read more

-

Categories: Workshop Setup & Tool MaintenanceFebruary 20, 2024Learn why Rockler is the best place to shop for Festool premium power tools.Read more