Additional Bevels for Turning Deeper Bowls

Bowl gouges: grind a second bevel, or even a third. Woodturning expert Ernie Conover explains how in this guide and video.

Curiously, how a bowl gouge's cutting edge is ground can affect how well it performs as a turner attempts to make deep, closed forms. To improve the cut, I grind my gouges in a specific way that includes a second bevel. To fully understand the benefit of secondary bevels, we need to first look at how a bowl gouge works and how its grind has changed over time.

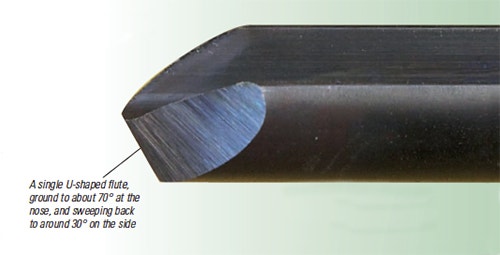

Here we see a traditional bowl gouge of about 1970 vintage. The flute is U-shaped, the edge is square to the axis of the tool, and the bevel is ground to a uniform 45°. It cuts shallow bowls of an open form very well. However, it does not do as well on deep, closed forms. That's because the geometry of the grind actually gets in the way of the cut.

In the 1980s, Irish turners found that by sweeping the face of the tool back at an angle and grinding the bevel asymmetrically, the gouge cut much better in deep, closed forms. Typically an Irish grind has the nose bevel ground to about 70° with the sides at 30° to 40°. The grind can be adjusted for even deeper cutting.

Deep Trouble

As a bowl gets deeper, the height of the sidewalls increase and the curved transition between the walls and the bottom becomes a much tighter radius. Since the tool must be presented very near the axis of the centers, it is like working in the bottom of a mineshaft. Our traditional gouge would need to be about 70° from the centerline to cut effectively. Even the Irish grind suffers here because the heel of the nose bevel forces the cutting edge up and away.

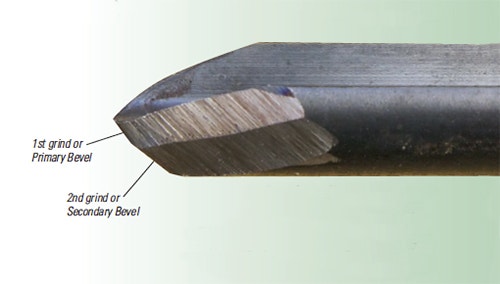

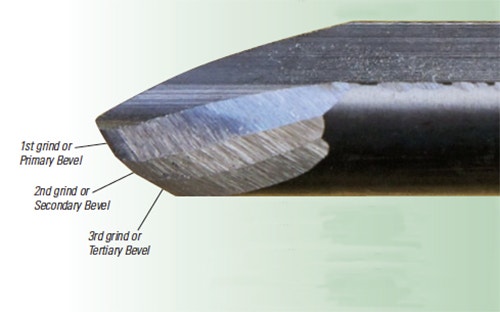

The solution to the problem is to grind a secondary bevel, thereby shortening the rubbing bevel and allowing much tighter radiuses to be cut. I grind the secondary grind without the aid of an additional specialty jig by simply setting the pocket of my Wolverine Jig closer to the grinder.

How wide to make the secondary bevel depends on how narrow you want the rubbing, or primary, bevel to be, and this will be dictated entirely by your work. Even for shallow bowls, a secondary grind is helpful. All of my photos in this article illustrate bevel sizes I think are appropriate for average faceplate work. As your skill increases and you tackle deeper vessels, you will benefit from grinding the secondary bevel bigger and the rubbing bevel smaller.

In the past, I have resisted teaching secondary grinds in my basic turning classes for logical reasons. My feeling was that the biggest struggle for a neophyte is to learn to "ride the bevel," which is a sense of feel much like riding a bike or snow skiing. My logic was that the bigger the bevel, the easier it is to sense being on it. Now, after introducing the secondary grind idea on the first day of the faceplate section of some of my basic turning classes, I can say that I was wrong! If anything, the neophyte has an easier time with a secondary bevel than without it.

Cut the Chatter

One final benefit to secondary bevels in general: When cutting on the outside of a bowl with a standard Irish grind, it is common to set up an unwanted chatter pattern caused by the interplay between the cutting edge and the heel of the bevel on the half-spherical surface you are creating. Like a corduroy road, it gets worse as the cuts progress. Lifting the handle slightly to make the tool level on the rest often corrects this problem. A secondary grind, no matter how it is achieved, is practically immune from this chatter problem.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks