Helpful Track Saw Enhancements

From specialized blades to guide rails and cordless options, there area wide variety of enhancements available for track saws that can improve both their accuracy and efficiency.

As track saws have grown in popularity with contractors, accessories have been developed that can make these portable tools even more valuable to those who make a living using them:

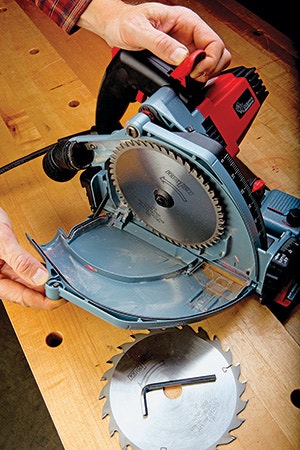

Dedicated blades now are available for ripping hardwood and cutting gypsum- or cement-bonded materials, laminate, engineered flooring, non-ferrous metals and plastics. If you can cut it with a circular saw, long-standing manufacturers like Festool will have a comparable blade to do the job with a track saw.

Guide rails in various sizes make it easy to cut a sheet of 8-ft plywood lengthwise, widthwise or into smaller panels. Festool, for instance, offers seven guide rail lengths in 31-1/2" (80 cm), 42-1/2" (108 cm), 74-3/4" (190 cm), 106-1/4" (270 cm), 118" (300 cm) and 196-7/8" (500 cm) options, plus the industry's typical rail size that measures around 55".

Or rails can be joined end-to-end with connector rods to extend their length. Guide rail channels also often can be fitted with specialized quick-grip clamps to secure them to workpieces or benchtops.

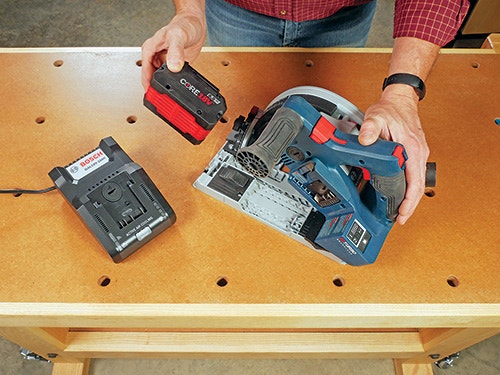

Cordless track saw options are on the rise, too, which should come as no surprise, given the enormous strides that have been made in lithium-ion battery technology and powerful brushless motors. Currently, Bosch, DeWALT, Festool, Makita, RYOBI and Milwaukee all have track saws that can help you "cut the cord," if battery power suits you best.

Worth the Investment?

If you browse track saw pricing, prepare for some sticker shock. You'll pay several times the cost of a quality circular saw or even more for a track saw and guide rail. These are premium tools intended for professional users. Only you can decide what the value of top-of-the-line motor features, added safety measures and an "autopilot" simple way to make straight cuts is worth to you.

I use my track saw almost exclusively for sizing down sheet goods, because it's easier to feed a lightweight track saw over 4x8s instead of wrestling the sheets across my table saw. And in truth, the cutting results are every bit as good with a track saw as I can achieve on my cabinet saw, whether that's splintery veneer-faced plywood or chip-prone melamine. Could I function without a track saw for general woodworking? Sure. But would I want to, particularly when I need to size down pricey cherry ply or 90-lb sheets of 3/4" MDF?

Not if I can possibly help it. A track saw affords me maximum control with the least amount of effort and yields clean, dependable results. I'm always at ease when I pull out the saw for a project, and that peace of mind and high performance is worth the tool's initial cost to me over time.

The only occasion when I've wanted more from a track saw is when ripping thick hardwood. Most track saws have a cutting capacity of around 2" with the saw set to 0 degrees. But on really dense lumber, some track saws can struggle through a thick cut. That's why I use mine for thinner materials and head to the table or miter saw instead, to size down thick solid stock.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks