How to Prevent Drifting While Ripping

I'm a beginning woodworker and I have had some trouble ripping large pieces of stock on my table saw. I am reasonably certain that the fence is aligned properly, and I check it every time before I make a cut of this type. The problem I'm having is that the end of the board seems to "drift" back toward the blade and I get a cut that is not square. What am I doing wrong?

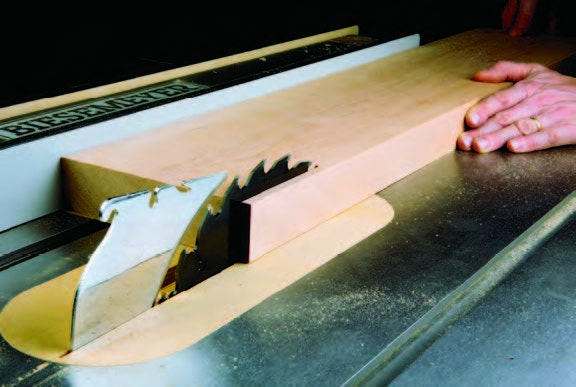

Michael Dresdner: You might benefit from a ripping fence. A standard saw fence protrudes far past the back end of the table saw blade. That means that if the wood moves after ripping (which it often does due to internal tensions being released), the back half will push away from the fence, moving the uncut part of the board with it. A ripping fence is a short fence that ends about midway through the blade and does not protrude beyond it. It allows the wood to move after it is cut without affecting the part you are still feeding into the blade. Some fence convert to a rip fence by sliding forward. You can create a makeshift ripping fence by adding a wooden "cheek" to the front half of the table saw fence with double sided tape. Make sure the board is flat and parallel.

Jeff Jacobson: It's possible that, like a lot of people, you are concentrating on keeping the workpiece tight to the fence at the beginning of the cut. What you need to do in this instance, though, is focus on the workpiece's relationship to the whole width of the fence: it's at the far end that you need to make sure the board and the fence are tight together. Of course, it's always possible that there's a mechanical problem, too: I'd check the alignment of your fence and blade again.

Linda Haus: There are so many variables playing a role in this, it's hard to tell what the problem might be. If you've run the board through a jointer, your jointer might be off. If it's a piece that you've previously ripped on the same saw, then the end of your board might be crooked from the previous cut. Without knowing more details of your situation, it's almost impossible to say for sure what your problem is.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks