How Much Router Do You Need?

It’s a good question to ask yourself before you start buying equipment. As with most things, bigger and better costs more, but changing your mind later on is still the most expensive solution of all. Rather than risking the expense of replacing an inadequate set-up, we recommend taking careful stock of your table routing requirements, and buying a router that fits the bill at the outset.

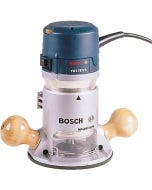

A modest 1-3/4 HP model will have the most attractive price tag and could turn out to be perfectly adequate, if your work tends toward small projects. It’s also a good choice for a small bench top table, where portability and storability usually trumps the need for loads of power. But if you’re planning to do anything beyond light-duty edge forming and the occasional groove or dado, a router in this class is likely to be a disappointment in the long run.

A step up to a 2-1/4 HP router will give you much more versatility. These routers consistently get a good report card, and will allow you to use larger edge forming and joinery bits, and raise panels with vertical bits without bogging down. For a hobbyist who doesn’t have to worry about production-class speed and durability, a router from this group often turns out to be just the thing.

But if the ability to tackle any size routing task you want is important, we urge you to look seriously at a router in the 3-1/4 HP class. Actually a little more router than you need for most handheld operations, most heacy duty routers make an excellent dedicated router table router. Best of all, you won’t ever find yourself wishing you’d sprung for a unit with more guts.

There are two things a router lifta> can give you: easy, accurate bit height adjustment and easy bit changes – both do-able from above the table. A lift will save you the awkward sub-table fumbling you’ll experience time and time again if you simply bolt a router and base to the underside of your router station. As important, the lift lets you make accurate bit height adjustments from above surface of the table using a handy drop-in “speed handle”. Each turn of the handle moves the bit up or down 1/16”. This adjustment ratio is gradual enough for exceedingly fine adjustments but still lets you crank the collet up above the table in a hurry when it’s time to change the bit.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks