Improving Table Saw Dust Ejection

I have an older table saw that has always given me a problem when ripping. I have tried many things to line it up, but it still sprays sawdust off the back of the blade at me with every cut. By the time I get a board ripped, I'm covered in sawdust; it shoots a stream right back. I have reset the blade aliment on the frame and the fence and checked it with a dial indicator. There is no runout on the arbor, and the blade only has .005". Anything you can think of that I have not done? It is a contractor type with a 1.5hp motor that hangs off the back. It also has all-new bearings, motor and saw arbor. I also run a link type belt on it. - Eugene

Tim Inman: My first reaction is to ask you to replace the blade. The difference between an average blade and a superior one is, well, superior! Since you seem to have addressed all the obvious mechanical issues, you may have already tried blade replacement, too. So, there is one other aspect you might check. This would help answer the question as to why that sawdust is being shot at you. What is directing that sawdust stream? Sometimes there are shields, guards or other elements below the saw surrounding the blade that might be involved. Can the sawdust escape from the blade tooth before it is hurled back up above the table? There should be a sawdust collection area below the table. Is it full or clogged? Does this saw require a vacuum dust collection system? I'm guessing "clearance" might end up being the missing link here, since you've double double-checked the obvious things like bearings, runout and angles. Give that sawdust someplace to go other than back up into your face.

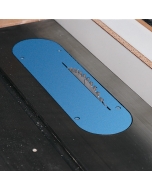

Chris Marshall: You don't mention what sort of throatplate you use on your saw. The big gap around the blade on a standard throatplate could be part of your dilemma. Switch to a zero-clearance throatplate instead. If the sawdust is deflecting off of some surface under the throatplate, as Tim suggests, or if your saw just suffers from poor dust ejection by design, closing up the gap around the blade will only help to cut down on the blizzard of debris coming up and out. It will also minimize tearout on splintery woods and keep thin slivers from falling down inside and getting trapped here and there. It's a simple saw improvement that really has no downside.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks