Builder Basics: Drawer-making Details

Drawers are some of the most useful furniture components we can build. You can make them in several ways with various corner joints. Here are some considerations.

Building drawers can bring out huge differences in maker philosophies. My friend and master woodworker Ian Kirby tells me that building a drawer was one of the most important construction tasks in the British Arts & Crafts furniture-making movement. When completed, the handmade drawer would fit perfectly in its opening to such a degree that when pushed in, it would cause a small audible rush of air. (Ian likens it to a piston in a cylinder.)

On the other hand, the late Mike McGlynn, a full-time woodworker, would just glue and nail drawer boxes together with butt joints. When I wondered about it, he boldly said, "They are bombproof. Purists be damned!"

Cabinet Drawer Components

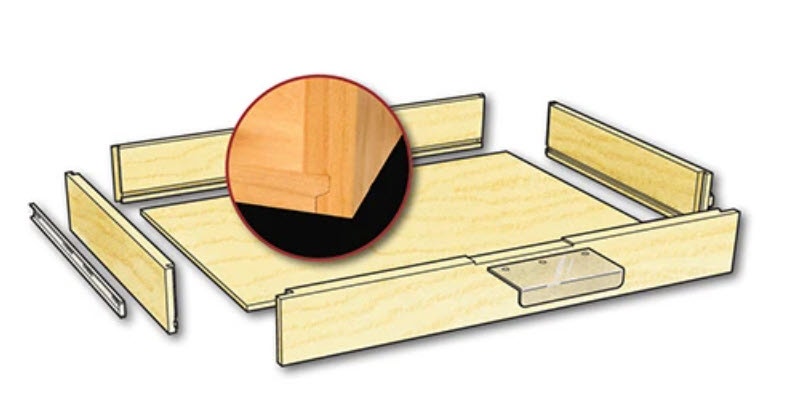

The most basic drawer consists of five components: two sides, a front and back and a bottom. Sometimes a separate drawer face is added to hide the drawer opening or the slide hardware.

But even with the most basic configuration, there are many options to be considered. How to join the corners is key among them.

The Drawer Lock Corner Joint

- Router-cut locking corner joinery

- Drawer front can also be a drawer face

- Option of solid wood or plywood front, back, sides

- Captured bottom panel

- Router or hand-cut dovetail construction

- Drawer face often applied over drawer front

- Wood front, back, sides

- Captured plywood bottom panel

- Saw or router construction

- Wood front, back, sides

- Typically installed with drawer slides

- Saw or router cut construction

- Applied drawer face

- Wood front, back, sides

- Typically installed with drawer slides

The drawer lock joint is a popular choice for joining the corners of a cabinet drawer box because it provides both strength and ease of assembly. This joint features interlocking profiles that create a larger glue surface and ensure precise alignment during construction. The result is a durable connection that can handle the wear and tear of daily use. Additionally, the drawer lock joint is relatively simple to cut with a set-up jig, router and drawer lock router bit.

Drawer lock bits rout a joint similar to a locking rabbet, but the rabbet is wedge-shaped so the parts fit tighter when clamped. A single bit routs both parts of the joint and is capable of routing joints for drawers with applied drawer fronts, and for drawer boxes where the finished front is integrated. You can also create joints where the finished front overlaps the side, in order to hide metal drawer sides.

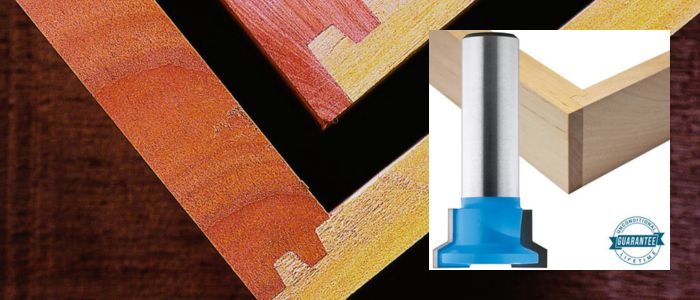

Dovetail Joints

The dovetail joint is a classic choice for joining the corners of a cabinet drawer box, prized for its exceptional strength and durability. Its interlocking design resists pulling apart, making it ideal for drawers that endure frequent use and heavy loads. Beyond its structural benefits, dovetail joints offer a timeless aesthetic, with their distinctive angled "tails" and "pins" adding a touch of craftsmanship to your work. While it requires precision to cut, the payoff is a sturdy, long-lasting drawer that stands up to wear and tear, all while showcasing superior woodworking skill.

Make Dovetail Joints Fast & Easy With:

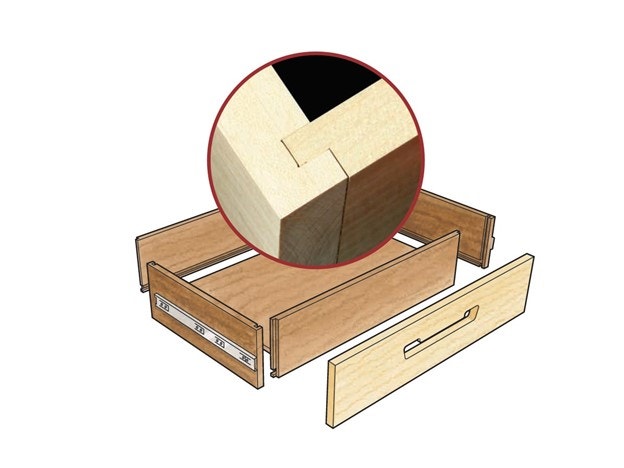

The Box Joint

The box joint, also known as a finger joint, is a popular method for joining the corners of a cabinet drawer box. It involves interlocking square "fingers" cut into the ends of two boards, creating a joint that is not only visually appealing but incredibly strong. The large gluing surface provided by the multiple fingers ensures excellent adhesion, making it ideal for drawers that need to withstand daily use. Box joints are also relatively easy to create using a box joint jig on a router table. Box joints offer a clean, decorative look that can be left exposed or painted over. In terms of durability and effectiveness, however, other corner joints such as box and rabbet-and-dado will serve perfectly well, too.

The Rabbet and Dado Joint

The rabbet and dado joint is a popular choice for joining the corners of cabinet drawer boxes because it provides a strong and precise connection while being relatively easy to create. This joint involves cutting a rabbet on one piece and a dado on the other, allowing them to interlock snugly. The interlocking design not only increases the strength and durability of the drawer but also helps align the pieces perfectly during assembly. The Perfect Fit Dado Jig lets you rout precise dados and grooves at any increment from 1/4" to 1" wide.

Video: What is a Dado Joint?

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks