What Is a Dovetail Joint?

Dovetails are simple in theory, but when you look at them more closely, they are a strong mechanical system.

The dovetail joint evokes woodworking as does no other system of joinery. This system of joinery, while not as old as the mortise and tenon techniques, is still ancient. The reasons that it has remained popular are several. First and foremost is that dovetails are a solid and reliable woodworking joint. If they are well-made, the combination of a large area for glue coverage associated with the mechanical quality of the joinery provides a durable and long-lasting joint. Most of us have opened drawers on an antique piece of furniture and have seen dovetails where it is clear that the glue has broken down...but the joint is still holding together. A butt joint or dowel joint would have fallen apart, but not the dovetail joint. Another reason is that they are attractive. The visual rhythm of the repeating tails and pins are simply pleasing to look at. If you are making dovetails by hand (or with a more sophisticated jig system like Rockler's), the pattern can be varied to accentuate the beauty of the joint. The third reason that dovetails remain highly popular is that the complexity of the joint, not easily mastered by novice woodworkers, implies quality. For many woodworkers, mastering the construction of a hand-cut dovetail is a goal that seems out of reach. For that reason, jig-guided dovetails are very much in the sweet spot of home shop woodworkers.

The Basics of the Dovetail Joint

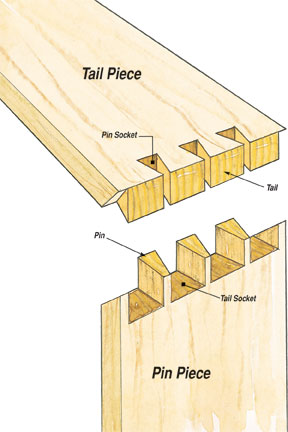

Dovetail joints consist of an interlocking and snugly fitted series of pins and tails. All the tails are cut into one piece of wood, called here the tail piece. Typically, the completed tail piece then serves as a template for marking and cutting the pins in the pin piece.

The joint pictured is a variation of a typical through – dovetail, in this case dressed up with a mitered corner. This joint is best achieved in a hand-cut dovetail.

While there are many subtle variations of the dovetail joint, an example of which is the mitered corner, the two main categories are through dovetails — where, as their name implies, the pins and tails extend all the way through the workpieces. The other main category is the "half blind" or "single lap" dovetail. It is called that because the drawer front overlaps the tail ends on the drawer side.

It is common for both types of dovetails to be used in a drawer. Through dovetails on the back corners and the single lap on the front corners.

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks