Setting Up Dust Collection Using Our Dust Management Guide

Congratulations! The fact that you are reading this blog article confirms that you value the importance of managing dust in your shop. Turning boards into chips, shavings and powder is an unavoidable byproduct of woodworking. And we woodworkers all know that we do our best work when we aren't shuffling through piles of planer shavings on the floor, coughing while we sand or constantly wiping dust off every surface it clings to.

We at Rockler Woodworking and Hardware have hundreds of innovative product solutions in our stores and online to help you design any dust collection system that fits your needs and budget—whether it's as simple as a dust extractor you connect to smaller power tools one at a time, or an expansive network of ductwork, fittings and hoses that stretches across your entire shop and connects to every machine.

Get The Dust Management Guide

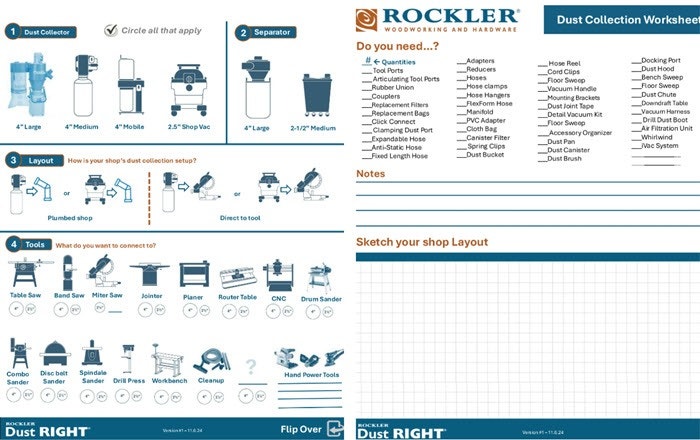

You may have seen our free Dust Management Guide handout when visiting your local Rockler store. If not, you can download and print out a copy by clicking here. It provides a quick visual tally of some of the many tool and hardware decisions you'll need to make when setting up dust collection solutions that meet your shop's specific needs. This article serves as a supplement to the Dust Management Guide. It will provide you a brief introduction to the four focus areas on the front of the sheet

1) Dust Collectors

2) Separators

3) Layout

4) Connecting Tools

As well as tips and product links to help you plan.

Getting Familiar with Dust Collection

If you are setting up your first dust collection system, here are several other excellent blog posts that explain the basics of woodshop dust management. We suggest that you read these first before proceeding:

- Setting Up The Best Dust Collection System

- How Dust Collection Systems Work

- What Makes Dust Collection Important

Choosing A Dust Collector

Choosing a dust collector type shouldn't be your first consideration when setting up a dust collection system—that's a decision that best comes after you know how much dust collection capacity will be required. Then you can be sure the machine you choose will have the power and capacity to work effectively and not leave you or your shop wanting for more. Our Dust Management Guide outlines several basic options, in large, medium and small formats:

Large (1,100 CFM or larger, 4" hose)

If your shop is equipped with a number of large stationary power tools, consider a dust collector rated for at least 1,100 CFM (cubic feet per minute) with a motor that's 1.5HP or more, such as our largest Dust Right Wall Mount HEPA Cyclone Dust Collector. When used as a portable dust collection system (moved from tool to tool), dust collectors of this size will produce ample air velocity and volume to whisk the debris away from even the largest home shop tools.

They're also an effective central dust collection solution for small shops—powerful enough to clear dust from more than one machine operating at the same time. Typically equipped with high-efficiency filters and large collection drums or bags, many can be plugged into 110-volt household current, so no special wiring is required! Some are single-stage machines that draw all the debris through the impeller and into a bag or container with no pre-separation. Others are two-stage, with a cyclonic separator built in help keep the main filter operating cleaner, longer.

With the exception of large stationary planers, most home shop woodworking machinery requires dust collection in the range of 350 to 600 CFM. Compact, entry-level dust collectors typically draw 650 CFM, which is adequate to service about one woodworking machine at a time using a moderate length of 4" dust collection hose connected directly to the tool. These medium-sized dust collectors typically have 1HP induction motors powered by 110-volt household current. They may incorporate a rolling stand for easy movement from machine to machine or mount to the wall to save floor space.

Small (Shop vacuums, dust extractors, 2-1/2" or smaller hose)

Hooked up to a handheld power tool shop vacuums provide plenty of suction. They can even work for some larger, but modestly demanding benchtop tools, such as a disc sander. Plus, shop vacuums easily roll to wherever you’re working. Their main downside is excessive noise and lack of power to handle the amounts of dust and large chips produced by larger stationary tools. Their filters are usually pretty basic and allow a lot of small particles—the kind that go airborne—to pass right through. Higher-end units offer better filtration, but they remain compromised by the lack of dust/debris separation and can clog quickly. Shop vacuums typically draw about 100 to 200 CFM.

Whereas shop vacuums are low-volume/high-velocity machines, dust extractors are just the opposite and move a larger volume of air a bit more slowly. This increases efficiency for handling fine dust, much in the way larger standalone dust collectors do. Lower air velocity (along with better insulation and tighter seals) also makes them quieter machines than typical shop vacuums. Nearly all dust extractors have an electrical outlet that pairs the machine with handheld power tools. Triggering the tool also starts up the extractor for automatic dust collection. Turning off the tool also turns off the extractor. Dust extractors are more expensive than simple shop vacuums, but their higher efficiency and considerably better dust handling—especially for extremely fine dust—makes them an attractive option. They can entirely take the place of a shop vacuum for ordinary wet or dry vacuuming tasks, too.

Adding a Separator

When a separator is installed between your dust collector and the tool or tools it services, all the dust- and particulate-contaminated air first passes through the separator where it slows down to some degree, due to cyclonic action. The heavier chips and shavings fall out of the swirling airstream and into a container or collection bag. Finer dust remains suspended and continues on to the dust collector. The benefit of pre-separating heavier debris from finer dust is that the dust collector's filter can operate longer and more efficiently, because the larger particulate can't prematurely clog it. Single-stage dust collectors (those without a built-in separator feature) and standard shop vacuums benefit most by adding a separator. Separators are sized to fit 4" dust collector hoses or 2-1/2" shop vacuum hoses.

Plumbing a Dust Collection System vs. Connecting Directly to Tools

A dust collection system works by capturing woodworking dust and debris in a stream of air and transporting it through the system's hose or rigid ductwork to a dust collector. The dust collector has to keep the air stream in the system moving at a certain velocity. It also has to move a fairly large volume of air to keep the debris aloft on its way to the collector. When designing a dust collection system, it is important to remember that air volume and velocity are interrelated. As you might expect, it takes a more powerful dust collector to move a large volume of air at a speed sufficient for effective dust collection than it does to move a small volume of air. Your dust collection system must be capable of delivering the minimum required CFM to each machine, and it must be able to do so while moving the air at the minimum recommended velocity.

The Pros and Cons of Plumbing a System

Having a network of rigid ductwork, fittings and hoses connected to all your power tools and the dust collector at once is an enticing thought. It lets you install the system along walls and the ceiling to get all this hardware off the floor and out of the way. A central dust collection system helps you work more efficiently and fluidly between machine operations, because you aren't stopping to disconnect a hose from one tool to connect it to another tool, rolling the dust collector from place to place. Instead, you can simply slide a blast gate closed at the previous tool, open the blast gate at the next tool and keep working. But a fixed-in-place dust collection system only works if it can move the correct volume of air at the correct speed to prevent clogs and loss of collection efficiency. It should be calculated mathematically and carefully built.

A central dust collection system also can be quite expensive, when all the required elbows, wyes, fittings, blast gates, ductwork, hangers and the correctly sized dust collector are taken into account. But the effort and cost will usually be worth the convenience and efficiency it brings, especially for larger shops with many machines. Rockler has an extensive line of dust collection accessories to build a system that's right for your shop. But be prepared to do your homework so you'll be pleased with the outcome.

There is a simpler and more economical "Option B," too. You can connect your dust collector to only one machine at a time. Of course, that means you'll have to switch a hose or hoses between machines while you work, which takes more time and effort. But Rockler can make that task easier with our Dust Right Quick-Change Handles for shop vacuums or dust collectors. The upside to a basic system like this is, you won't need as a large (or expensive) of a dust collector, because it doesn't need to meet the entire airflow and velocity requirements of a plumbed, whole-shop system. Or consider setting up a limited system of rigid ductwork and hoses. You could use a medium-sized dust collector and plumbing to service, perhaps, only your jointer, planer and table saw. Then use a shop vacuum or dust extractor as mobile dust collection for your router table, benchtop spindle sander and a small band saw.

Here are a few tips to consider for whatever dust collection system you come up with:

Keep runs of flexible ribbed hosing as short and straight as possible. - While hose is convenient and easy to use, the ribbing reduces airflow efficiency. Long lengths of hose tend to clog more easily.

Maximize airflow efficiency when using rigid ductwork - by keeping turns at room corners and around obstacles smooth and gradual. Use wye connectors instead of tee connectors where branches of ductwork separate from the main "trunk" line. Keep the duct diameter as large as possible for as long as possible before using reducers to connect ducts to tools with smaller dust ports.

Use gravity to your system's advantage. - Running ductwork vertically up to the ceiling will challenge airflow more than when it is installed at gentler angles or horizontally.

Install a blast gate in the branch line of ductwork close to each tool - so you can close off airflow to any tools you aren't using for the task at hand. The more airflow you can preserve, the better the overall dust collection efficiency will be.

Connecting Tools to Dust Collection

There are two main alternatives for connecting tools with 4"- or 2-1/2"-diameter dust ports to a dust collector or your dust collection system. You can attach the ribbed hose directly to the tool port with a hose clamp — a simple solution if you don't need to remove and reinstall it very often. Or, for a handy temporary connection, you can install an adapter of many varieties on the hose to connect it to the tool port without the need for a hose clamp. For one example, consider our Dust Right 4" Quick Change Handle. The back end of the handle fits 4" dust collection hose, held in place with a hose clamp. The front end of the handle simply-friction fits into Dust Right 4" Quick Change Tool Ports or Quick Change Adapters that mount to the tool's dust collection port with a flexible rubber boot and hose clamp. The same handle can also serve as the connection point for a bench nozzle and floor sweep, to help make general shop clean-up tasks easier.

Some benchtop power tools have dust ports that are made to fit a standard shop vacuum nozzle with no modification required. But if the tool's dust port won't quite accommodate the nozzle, a Dust Right Conversion Port with rubber boot and hose clamp can solve the problem. Or try our Dust Right Quick Change Shop Vacuum Handle instead. It enables you to connect 2-1/2" dust collection hose to 2-1/4" ID tool ports or use the hose with the extension wands and other tools that come with your vacuum.

Smaller handheld power tools have a variety of different dust port sizes and shapes. The lack of uniformity once made these tools difficult to attach to a shop vacuum. But Rockler's Dust Right Flexiport Power Tool Hose Kit with Click-Connect now makes it easy. Flexible fittings in the kit conform to a wide variety of power tool ports. These FlexiPorts then attach with a simple click to a Click-Connect fitting on the expandable vacuum hose that comes with the kit. An adapter for the hose plugs into the hose inlet of standard shop vacs, so you can use the FlexiPort hose in place of your shop vacuum hose.

Rockler has many other solutions for connecting power tools to dust collection. For a more complete overview, take a look at this post on dust collection fittings

Consider Cleaning the Air, Too!

While our Dust Management Guide gives you a lot to think about related to solutions for managing large amounts of woodshop dust, it doesn't touch on the issue of airborne dust. Despite your best efforts to create effective dust collection, some amount of extremely fine dust will inevitably escape. Wearing a dust respirator and opening windows or the garage door are a few simple remedies you're probably already doing to cut down on the amount of dust you breathe while woodworking. Nevertheless, micro-fine dust continues to permeate the air and can remain suspended for days before settling out.

Installing a powered ambient air cleaner in your shop offers you an additional line of defense against dust you can't even see and yet are breathing. Rockler offers two models of ceiling-mounted Dust Right Air Filtration Machines for either small or larger shops. Their replaceable filters trap dust particles down to 1 micron (about the thickness of a human hair) and can scrub all the air in your shop multiple times per hour. They're quiet, programmable, remote-controlled and offer the added benefit of bright, built-in LED task lights. You'll be able to breathe easier while also seeing better—it's a win/win!

Keep the inspiration coming!

Subscribe to our newsletter for more woodworking tips and tricks